Another method involving toner heat transfer was fine for thick traces but the fine ones would get flattened when pressed too hard. That would be the case even when using a laminator.

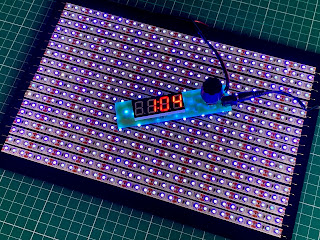

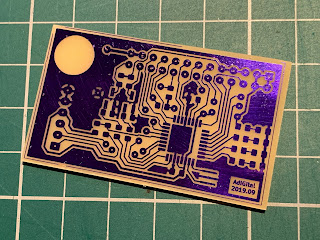

Lately I decided to go for photo sensitive dry film. I ordered some UV led strips and created a lamp that yet has to get its enclosure. I also made a simple timer that was the first board to test the new method.

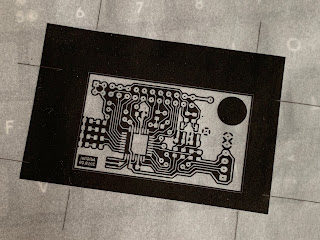

At first it was great experience but after a while I started noticing imperfections like trapped bubbles or the film not sticking properly. I followed guides I found online. Treated the copper with steel wool, applying the film in water, running through a laminator etc. After closer inspection I found one of the problem was the film itself, which I got one of the cheap ones on Amazon. Here is how it looks:

As you can see the surface is not even and there is lots of thin spots. So it's quite important to find an area free of them.

Another issue could have been the board preparation. Giving the copper a steel wool treat may not be the best option for the film adhesion. What I did with my last experiment was not to use it. Instead I treated the board only with Brasso polishing solution. It took just slightly longer that the wool but the finish was perfect.

I then applied the dry film directly. I didn't use water or any cleaning solution afterwards. I used some Blu-Tack to hold the board to the desk, peeled a fragment of the protective film and starting from one corner I pressed the film to entire board. The film stuck perfectly.

Initially I used OHP film as the media to print the mask. I had problems with toner sticking evenly to larger areas or even to some thicker tracks. That required me to print 2 copies and use them one on top of another. That in turn caused another issue, which was my printer. The two copies were not identical in size. Probably due to the mechanism imperfection one would always be slightly longer. The same was for tracing paper but at least the paper would absorb more toner and more evenly.

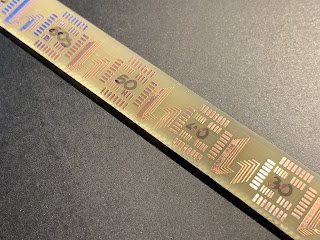

The goal was then to use just one piece of mask and for that the key was proper calibration of the exposure time and the distance between the lamp and the board. A strip of board with repeating pattern did the job. I used 0.2mm tracks with 0.1 & 0.2 mm clearance, and 0.25mm tracks with 0.2 & 0.3 mm clearance. I don't think I would ever go below that.

For the distance of 15cm the perfect exposure time for my lamp was 40 seconds. It shows I can't use the 0.1mm clearance but 0.2 is spot on.

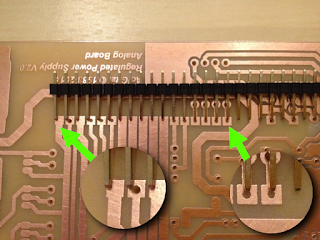

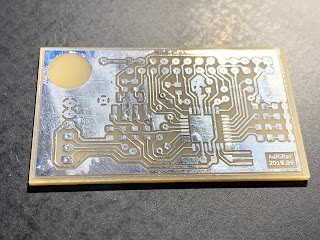

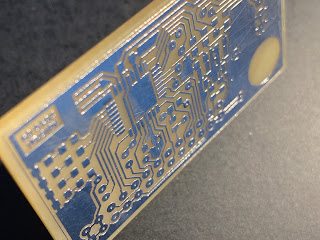

Here is the etched result:

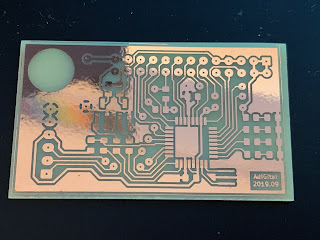

And the last step is to protect the copper and make it easy to solder. For years I'd use dissolved in alcohol organic flux - rosin. It's great and cheap solution but I wanted something more "professional". On one occasion I tried chemical tinning but wasn't happy with the result. Soldering wasn't really easy and the solution itself may pose health risk.

I made a DIY wide soldering tip. I used an old heatsink made of copper and one of unused soldering tips.

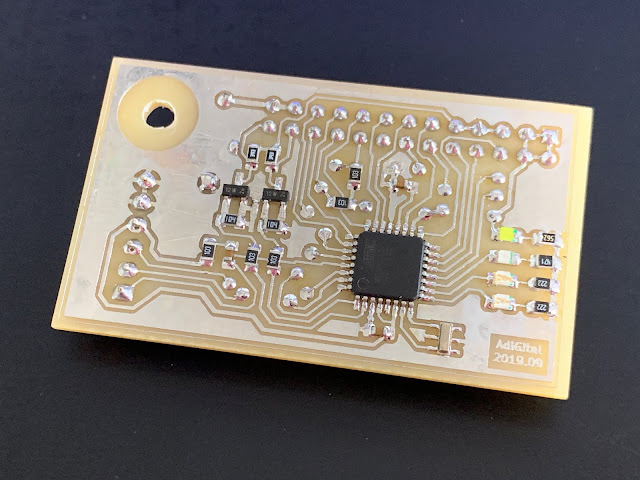

This allowed me to tin the board with relatively even layer of solder forming nice ant solid finish:

Soldering the elementals was a breeze and the final component looks quite good: